Experience in Ring Substation Maintenance –

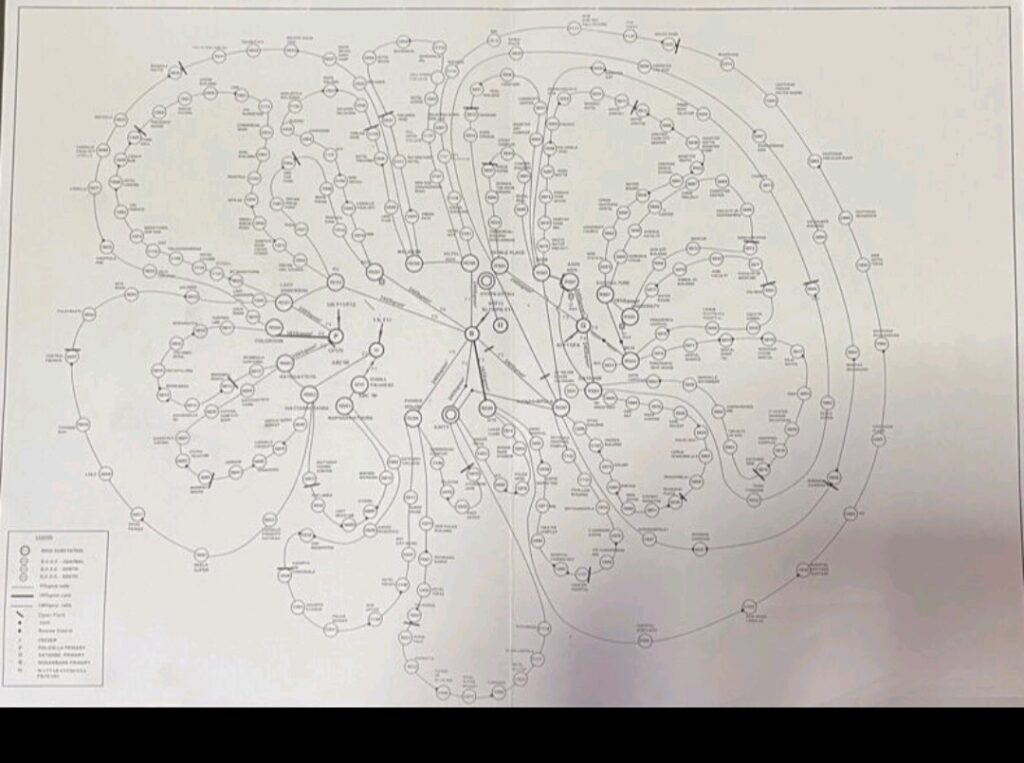

Maintenance of a ring substation where 11kV power is transmitted underground to serve bulk power consumers.

With around 20 main ring substations in the city, regular maintenance is crucial to ensuring a stable and efficient power supply.

Key Maintenance Tasks:

✔ Isolating and Earthing – Ensuring safety before maintenance

✔ Disassembling Key Components – Including Air Circuit Breakers (ACBs) and Vacuum Circuit Breakers (VCBs)

✓ Cleaning and Lubrication Applying grease where necessary and using critical spray for cleaning

✔ Vacuuming and Dust Removal – Maintaining optimal performance and reliability

Why are Vacuum Circuit Breakers (VCBs) used in Ring Substations?

VCBs play a critical role in medium-voltage power distribution by providing reliable protection against faults. Unlike ACBs, which use air as the arc-quenching medium, VCBs use a vacuum to extinguish arcs efficiently, ensuring:

✔ Minimal maintenance due to their sealed design

Long service life and high reliability

→ Faster arc extinction, reducing equipment wear and enhancing system stability

Routine maintenance is carried out every five months to enhance efficiency, reliability, and safety. This experience has provided valuable insights into substation operations, power distribution, and the critical role of protection systems.

RMU Unit System

Ring Main Unit System in the city 20 units