Choosing Between Regular and Liquid-Filled Pressure Gauges: What I Learned

I’ve worked with pressure gauges across different setups, and I’ve realized that picking the right one really depends on where and how you’re using it. Let me break it down for you:

Regular (Non-Liquid Filled) Pressure Gauges

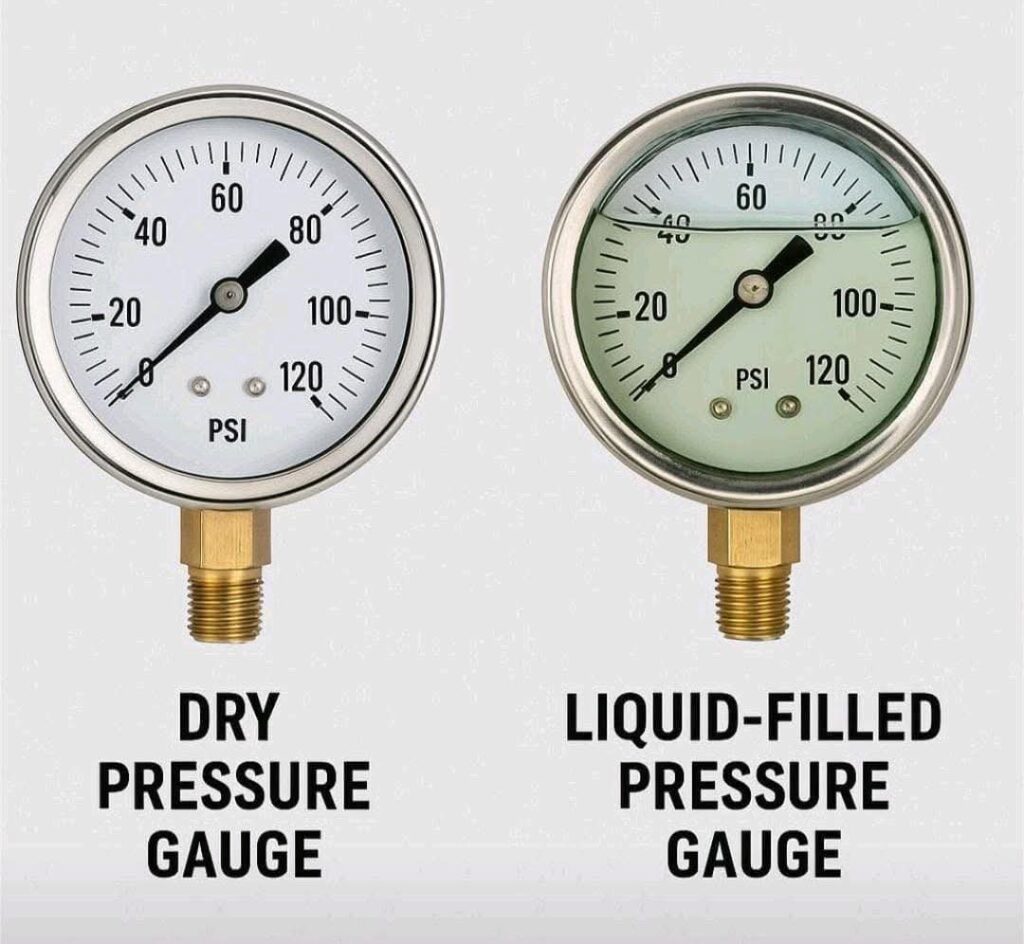

These are your classic, no-fuss gauges. They have a dry, clear face and the pointer moves freely without anything holding it back.

I usually reach for these when I’m working in stable, low-vibration environments — like HVAC systems, labs, or even simple home water systems. They’re affordable, easy to maintain, and perfect for calmer settings.

But here’s the catch: if there’s a lot of vibration or moisture around, regular gauges can start acting up. Vibrations make the readings jumpy, and moisture can creep in and cause rust. In rough conditions, they just don’t last as long.

Liquid-Filled Pressure Gauges

Now, if I’m dealing with a tougher job site, I always go for liquid-filled gauges. These are packed with glycerin or silicone inside, which helps dampen vibrations and keeps the needle nice and steady. Plus, the liquid protects the internal parts from dust, moisture, and even corrosive materials.

They’re a bit pricier, but believe me, they’re worth it when you need something that can stand up to factory floors, oil refineries, or outdoor weather.

One thing I keep in mind: glycerin can thicken up when it’s freezing cold. So, if I’m working in colder climates, I choose silicone-filled gauges instead. Also, I’m careful not to use them in places where they might get physically damaged — a leak would be a real hassle.

When Do I Use Which?

Regular Gauges: I pick these when the job’s indoors, the pressure is steady, and the budget is tight.

Liquid-Filled Gauges: I go for these when there’s a lot of vibration, harsh weather, chemicals flying around, or when precision is non-negotiable.

A Few Tips I Always Follow

Cost vs. Longevity: Sure, regular gauges are cheaper at first. But liquid-filled ones save me from constantly replacing broken gauges.

Environment Comes First: If there’s any chance of moisture, dust, or extreme temperatures, I don’t even think twice — liquid-filled is the way to go.

Safety Matters: For anything critical, I never risk it — I stick with the reliability of liquid-filled gauges.

Real-World Examples from My Work

A noisy, vibrating factory pump? Definitely needs a liquid-filled gauge.

My home water heater? A regular dry gauge does just fine.

An Arctic pipeline project? I made sure we used silicone-filled gauges to handle the freezing cold.