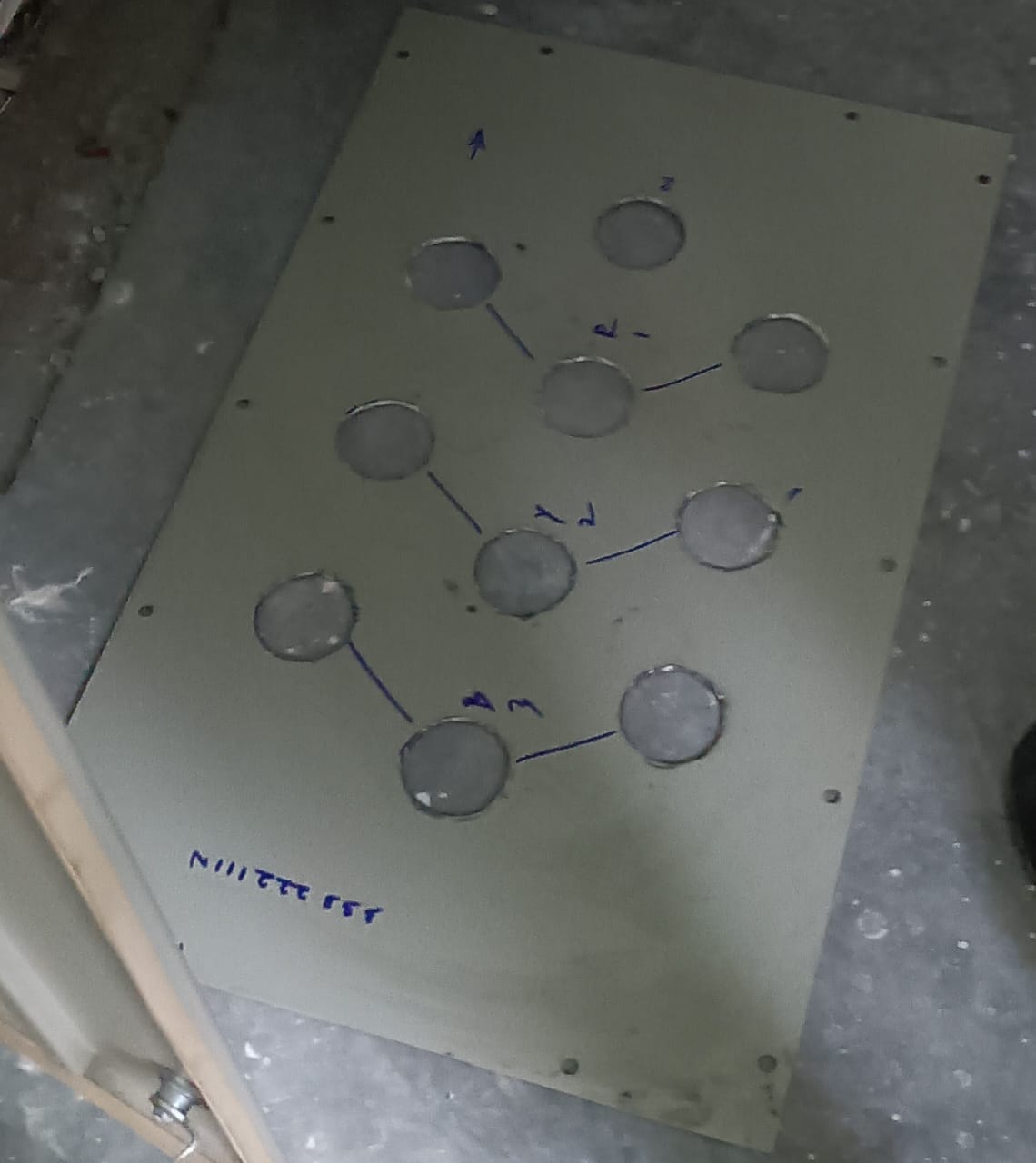

As you can see when we want to take cable for the termination we mostly have to drill holes in the plate. many time from bottom sometimes from top but occasionally from side of the panel board. for drilling we use equipment call hole saw . it comes form different sizes and different materials.

for electrical panels they mostly come by metal so it has to be drilled by hole saw specially called carbo pit. while we can keep for long time. while drilling the hole we have to spread water to slow down the heat and loosing metal strength.

make sure you drill it at once if not

drilling on a half made hole not easy . drilling machine can go here and there. make sure you choose the correct hole saw for the cable . if not sure keep the hole saw on the cable with outer cover and choose a one which is bigger than that even 3mm. because you are gonna put gland over that. you need space for the gland also.

mark the cable according to the bus bar ends if not you will have to bend from one corner to other terminal. make sure you get a clear idea how many cables are coming and future prediction of upgrades. then you can leave spaces for them too.

if you are drilling holes after cables are installed make sure you don’t spread and bend the cables so that they will loosen up the grip with glands.