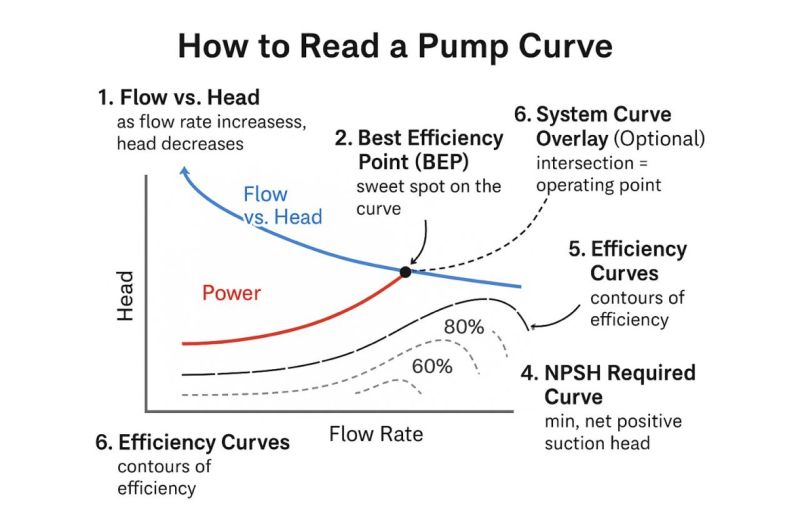

How to Read a Pump Curve – A Must-Know Skill for Every Engineer

💧 One of the most essential tools in pump selection is the pump performance curve. But many engineers overlook how much valuable information it holds.

Here’s a quick breakdown to understand and use it effectively:

✅ 1. Flow vs. Head

* The core of the curve: as flow rate increases, head decreases. * Helps match your system head curve with the pump’s actual performance.

✅ 2. Best Efficiency Point (BEP)

* The sweet spot of the curve — where the pump runs most efficiently.

* Always try to select a pump that operates close to BEP for longer life and less energy loss.

✅ 3. Power Curve

* Shows how much power the pump will draw at various flow rates.

* Useful for motor sizing and energy analysis.

✅ 4. NPSH Required Curve

* Indicates the minimum NPSH needed to avoid cavitation at each flow rate.

* Make sure your NPSH Available (NPSHa) is higher than this line.

✅ 5. Efficiency Curves

* Overlay lines showing % efficiency zones (60%, 70%, 80%, etc.)

* Great for comparing performance across models.

✅ 6. System Curve Overlay (Optional)

* If available, overlay your system curve on the pump curve.

* The intersection = your operating point. That’s where the pump will perform in reality.

💡 Pro Tip: Understanding pump curves helps you avoid over-sizing, prevent cavitation, and ensure optimal performance in real-world conditions.