⚠️ The Silent Guardian of HVAC Systems: Importance of Pressure Transmitters and Proper Maintenance

Modern HVAC systems depend heavily on sensors and automation to maintain efficiency, safety, and reliability. Among these critical devices, the pressure transmitter plays a major role in monitoring system performance and protecting expensive equipment.

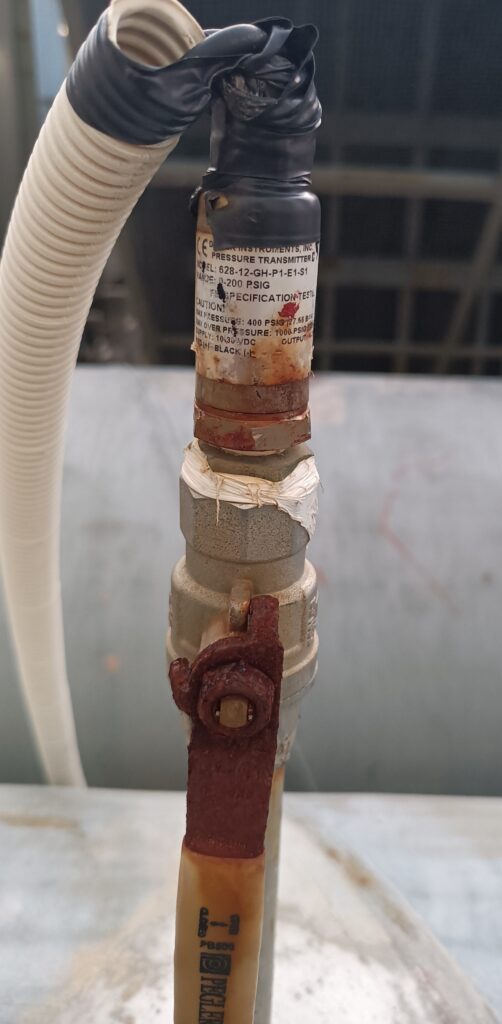

A recent field observation of a pressure transmitter installed on an HVAC piping system highlighted serious maintenance concerns such as corrosion and possible contamination. These conditions emphasize why regular inspection of instrumentation is just as important as maintaining mechanical components.

🔍 What is a Pressure Transmitter in HVAC Systems?

A pressure transmitter is an electronic device that measures pressure inside pipes and converts it into a signal (usually 4–20 mA or digital output). This signal is sent to:

Building Management Systems (BMS)

HVAC control panels

Monitoring and alarm systems

Pressure transmitters are commonly used to monitor:

✔ Chilled water pressure

✔ Hot water pressure

✔ Refrigerant pressure

✔ Pump discharge and suction pressure

✔ Air handling unit (AHU) coil pressure

⚙️ Why Pressure Monitoring is Critical

Pressure is one of the main indicators of HVAC system health.

Proper monitoring helps to:-

Maintain correct water flow through chillers and coils

Detect pump failures or blockages

Prevent pipe bursts or leaks

Ensure efficient heat transfer

Optimize energy consumption

Without accurate pressure data, HVAC systems may operate inefficiently or even fail unexpectedly.

⚠️ Issues Observed in the Installed Pressure Transmitter

The pressure transmitter shown indicates several warning signs that maintenance teams should never ignore.

- External Corrosion

Visible rust formation around the transmitter and fittings indicates exposure to moisture or condensation. This can lead to:

Sensor damage

Signal inaccuracies

Mechanical failure

Leakage at connection points - Poor Insulation or Protection

Damaged or improper insulation around HVAC piping can cause condensation buildup. Over time, moisture exposure accelerates corrosion and reduces transmitter lifespan. - Risk of Measurement Errors

Corroded impulse connections or blockages can cause:

Incorrect pressure readings

False alarms in BMS systems

Poor system control performance

In HVAC automation, incorrect data can lead to energy wastage and system instability.

💡 Consequences of Neglecting Pressure Transmitter Maintenance

Ignoring instrumentation maintenance can result in:

✔ Pump damage due to improper pressure control

✔ Reduced cooling or heating efficiency

✔ Increased energy consumption

✔ Unexpected HVAC system shutdowns

✔ Higher repair and replacement costs

In commercial buildings, these failures can affect occupant comfort and operational continuity.

🛠 Recommended Maintenance Practices

To ensure reliability and accuracy, HVAC teams should follow proper preventive maintenance procedures.

✔ Routine Visual Inspection

Check transmitters for rust, condensation, loose fittings, and physical damage.

✔ Verify Calibration

Regular calibration ensures accurate pressure readings and proper system control.

✔ Protect Against Moisture

Ensure proper insulation of chilled water lines

Use weatherproof enclosures where required

Seal cable entries properly

✔ Check Impulse Lines and Valves

Blocked or air-filled impulse lines can cause inaccurate measurements.

✔ Replace Aging Sensors

Pressure transmitters have a limited service life. Timely replacement prevents unexpected failures.

🌱 Role in Energy Efficiency and Smart Building Operation

Pressure transmitters are key components in energy-efficient HVAC systems. Accurate pressure monitoring helps:

Maintain optimal pump operation

Reduce unnecessary energy usage

Support predictive maintenance strategies

Improve overall building sustainability

✅ Conclusion

Pressure transmitters may appear as small devices within HVAC systems, but their role is vital for safe and efficient operation. The observed corrosion and deterioration in field installations serve as a strong reminder that instrumentation maintenance should never be overlooked.

A well-maintained pressure monitoring system improves reliability, reduces energy costs, and extends the life of HVAC equipment.