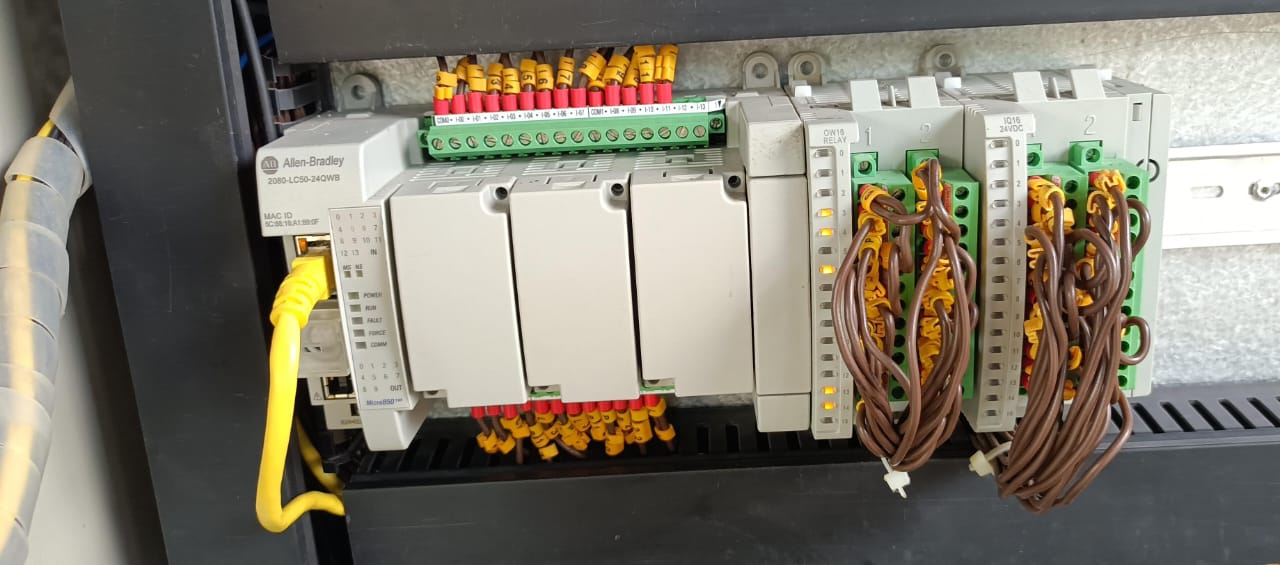

Allen bradley PLC unit

Modbus Protocol: Modern Uses and Process

Figure :- Allen bradley PLC unit

Modbus is a master-slave communication protocol used for connecting electronic devices, primarily in industrial settings. Developed in 1979 by Modicon (now Schneider Electric), it remains widely used today.

*Modern Uses:*

1. Industrial Automation: Modbus is used in SCADA (Supervisory Control and Data Acquisition) systems, PLCs (Programmable Logic Controllers), and RTUs (Remote Terminal Units).

2. IoT (Internet of Things): Modbus enables communication between IoT devices in industrial environments.

3. Building Automation: Modbus controls HVAC, lighting, and security systems.

4. Energy Management: Modbus monitors and controls energy usage in industrial and commercial settings.

5. Water and Wastewater Management: Modbus is used in water treatment and distribution systems.

*Process:*

*Modbus Communication Process:*

1. Master Device (Client): Sends commands and requests data.

2. Slave Device (Server): Responds to requests and sends data.

3. Message Structure: Modbus messages consist of:

– Address (device ID)

– Function Code (action requested)

– Data (information exchanged)

– Error Check (ensures data integrity)

4. Communication Modes:

– RTU (Remote Terminal Unit): Serial communication.

– ASCII: Text-based communication.

– TCP/IP: Modbus over Ethernet.

*Modbus Function Codes:*

1. Read Coils (0x01)

2. Read Registers (0x03)

3. Write Single Register (0x06)

4. Write Multiple Registers (0x10)

*Advantages:*

1. Simple and widely supported.

2. Low-cost implementation.

3. Reliable and robust.

*Challenges:*

1. Limited security features.

2. Vulnerable to cyber attacks.

3. Not designed for large-scale networks.

Security Considerations:*

1. Implement firewalls and VPNs.

2. Use encryption and secure authentication.

3. Regularly update firmware and software.

Modbus remains a widely used protocol in industrial settings due to its simplicity and reliability. However, its limitations and security concerns necessitate careful implementation and ongoing maintenance.