What are the reasons for failures in cable box?

1. **Moisture Ingress:** –

Water or moisture entering the cable box can cause corrosion of metal parts, leading to poor electrical contact and eventual failure. It can also lead to insulation degradation, causing short circuits or ground faults.

2. **Overheating:**

– Poor ventilation, excessive current loads, or bad connections can cause overheating within the cable box. Over time, this can degrade insulation materials and potentially cause insulation breakdown or even fire.

3. **Poor or Loose Connections:** –

Improperly torqued connections or vibrations can cause connections to become loose. This leads to increased resistance at the connection points, resulting in localized heating and potential failure.

4. **Aging of Components:** –

Over time, the insulation and other components within the cable box can deteriorate due to environmental conditions, leading to eventual failure.

5. **Electrical Stresses:** –

Electrical stresses, such as over voltage or transients, can cause partial discharge activity or insulation breakdown within the cable box, leading to failure.

6. **Contamination and Pollution:** –

Dust, dirt, or other contaminants accumulating inside the cable box can lead to tracking across the surface of insulating materials, eventually leading to electrical breakdown.

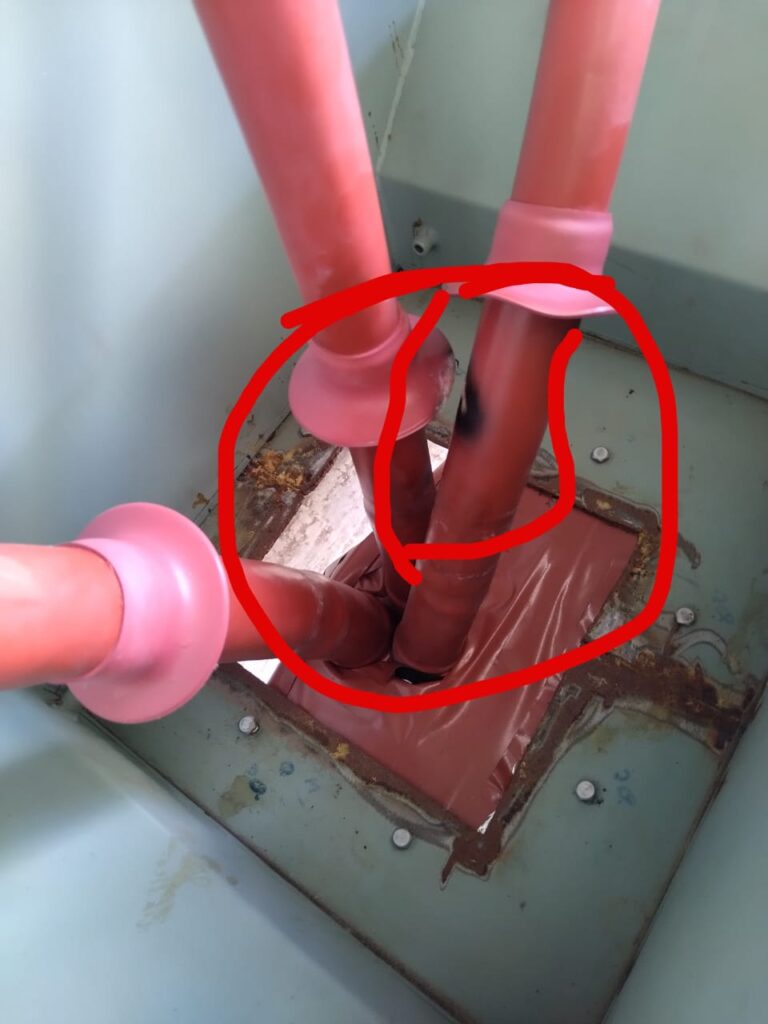

7. **Mechanical Damage:** –

Physical damage to cables or connectors during installation or maintenance can weaken the system and lead to eventual failure. cables weight also can pull the porcelain insulator down and cause cracks.

8. **Insulation Failure:** –

Degradation or breakdown of insulation material, due to factors such as thermal cycling, electrical stress, or chemical exposure, can lead to short circuits or ground faults.

9. **Poor Installation Practices:** –

If the cable box is not installed correctly, such as improper sealing or lack of stress relief for cables, it can lead to premature failure.

To mitigate these issues, regular maintenance, proper installation, and environmental control are critical. Regular inspections can also help in early detection of potential issues before they lead to complete failure.

#transformer #electrical